APPLICATIONS FOR METAMATERIA PRODUCTS

Novel Porous Ceramic Composites

Our environmental products utilize a highly porous, unique ceramic composite. This composition includes an alumino-silicate binder along with other added fillers. Fillers can range from zeolite to calcinated clays to carbonate minerals to iron powders. The alumino-silicate binder represents ~25% of the final product, while the filler percentage can be varied to meet requirements of each environmental product. Our environmental product typically contains more than 80% of open space. This open space is interconnected porosity with a density of 0.4-0.6 gm/cc. Our environmental products, built on highly porous ceramic composites offer tremendous surface area yet easily allow liquids and gases to pass through unencumbered. The surface area of our environmental products can be tailored (ranging typically from 15 to 250 m2/g). These environmental media offer longer life, shorter contact time and higher contaminant removal rates.

Our ceramic composite products are manufactured by blending reactive liquids. By utilizing liquids, many different shapes can be formed, as seen below. These generally are unfired ceramic products and the porosity occurs during the gas expansion phase. Ultimately the product forms into the desired shape or monolith.

Porous ceramic composites offer a platform for active materials

High surface area, open porous structures can provide a platform for adding active materials, such as

Beneficial bacteria for bioremediation

Nanomaterials for capture or breakdown of contaminants

Ligands/surfactants for capture of contaminants.

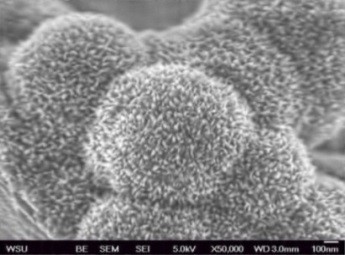

Surface is 95 m2/g.

Nano-iron oxyhydroxide acicular crystals grow on our porous ceramic composites with included iron. Surface area is over 100 m2/g.

Porous Product Characteristics

Porous platform with high surface area (15 - 200 m2/gram)

Alumino-silicate bonded with >80% interconnecting pores

A tri-modal, hierarchical pore structure – ranging from large to nano in size

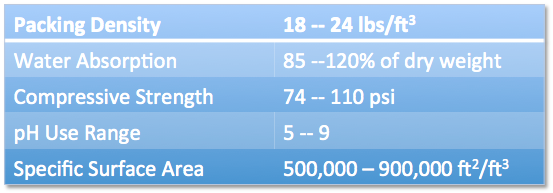

Physical Properties

These are highly porous materials whose properties can be varied by composition and processing.

Water Flow

Water easily flows through the open porous structure. The tri-modal pore structure creates turbulence, which facilitates contaminant removal by enhancing contact with the beneficial bacteria, nanomaterials or other additives used for sorption or conversion. Testing and field data shows flow through 4 inches of media at over 100 gpm/ft2. Our porous composite media shows very low pressure drop when compared to typical sand filter. Similar results have been found for air flow.

Note: The high surface area allows large colonies of bacteria to adhere without significant reduction in flow.

Applications

Phosphate Capture and Recovery at high and low concentrations

Nutrient Removal (Nitrite, Ammonia & Nitrate)

Removal of Metal Ions (e.g. As, Pb, Se, Fe, Mn, Cu)

Hydrocarbon Removal from Water

Perchlorate Removal

Hydrogen Sulfide Removed from Water & Gas

Waste Gas Clean-Up