PROBLEM

Phosphorus (P) is a key component in modern fertilizers, added to food and beverages and to water for corrosion control. Some 80% of P is used in the fertilizer on which world agriculture depends. However, P is accumulating worldwide in water bodies and causing harmful algae blooms (HAB). These HAB degrade water quality, create toxins and deplete dissolved oxygen, allowing toxic ammonia to form, which kill marine life. HAB can also poison drinking water and limit the use for recreation. One part of P in water can grow 100 parts of Algae.

See a Complete Summary on Topic of Phosphorus Removal

Learn More About Phosphorus Removal & Recovery

PO4 Sponge - Attractive for Both Removal and Recovery

MetaMateria’s PO4 Sponge offers an effective way to remove soluble P from water. This is a unique, porous, high surface area material that contains iron-oxyhydroxide nano-crystals, providing an extremely large number of sites for phosphate ion sorption. The product can be regenerated and reused multiple times and P can be recovered. The PO4 Sponge provides:

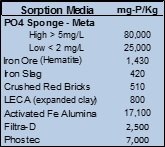

High Absorptive Capacity. Higher soluble P absorption capacity - typically more than 5 times higher as shown in the table compared with other sorptive materials.

Can be used with Low and High Concentrations. Removes phosphorus at both low (< 0.2 mg/L) and high (200 mg/L) levels.

Cost Effective. Less media is needed to remove P

Long Life. Can continually remove P for years

Excellent Hydraulic Water Flow. Water easily passes through media due to interconnecting pore structure to reach absorption sites.

Can be Regenerated & Reused. Media can be regenerated and reused. This lowers an average cost by 80% versus a single usage.

Phosphorus Easily Recovered. PO4 ions removed during regeneration are recovered as precipitates (e.g. calcium phosphate).

Our PO4 Sponge is available in different shapes and sizes, providing flexibility for use of the product in systems designed for a variety of applications. This is a highly porous material with nanocrystals of iron oxyhydroxide grown on pore surfaces. Capacity expressed in mg of PO4/gram of Fe shows that over 3,000 mg of PO4/gram of Fe is removed, considerably higher than other media.

Using PO4 Sponge

PO4 Sponge can be . . .

1. packaged as a monolith

2. used as packed beds

3. placed into moving water

1. For a single pass, the best results occur using a monolith (i), such as the cartridge shown.

2. In beds made with smaller pieces (cubes), so open spaces exist and a portion of the water bypasses the media, to recycle some discharge water which enhances P removal. Longer contact increases P removed.

3. If placed directly into water, plastic holders or open weave bags can be used to suspend media in flowing water.

PO4 Sponge Regeneration allows media to be reused, feasibly, more than 10 times due to very little mechanical or chemical degradation being observed with reuse. The percentage of P recovered after each use following regeneration is fairly consistent. In regeneration, sorbed PO4 ions are removed by circulating a base chemical (e.g. sodium hydroxide) through the PO4 Sponge

PO4 Sponge Applications

PO4 Sponge is sold commercially for smaller applications and is being examined for other applications, where results are encouragingly positive. Field tests of PO4 Sponge are done on-site or use water obtained from commercial sites. Testing includes:

On-Site Waste Treatment (Septic) Systems containing 6 to 10 mg/L of P

Municipal waste treatment water ranging from 2 to 4 mg/L (six different sites)

Municipal Waste filtrate from sludge compactions ranging from 30 to 130 mg/L

Agriculture runoff water containing 0.8 to 0.1 mg/L

Lake and Stream water where P below 0.5 mg/L

Chemical-Free swimming pools where P needs to be below 0.1 mg/L

Industrial waste water (food processing plants) ranging from 5 to 150 mg/L

Learn How To Remove Phosphorus from Agricultural Runoff

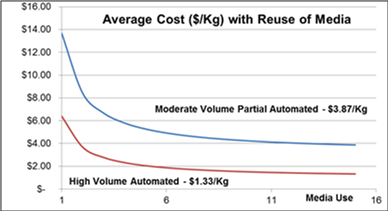

Cost to Remove Phosphorus

The cost to remove P using PO4 Sponge looks attractive for many applications at both low and high P concentrations. It competes well with other absorbents, especially when P needs to be under 0.5 mg/L. As a result, the PO4 Sponge provides a simpler approach to removal that can have a lower capital and operating cost.

The average price for the PO4 Sponge declines with reuse, since regeneration costs are much less than initial cost. This graph shows how the average cost is lowered with multiple use and the effect of lower media cost with volume production. After 6 uses, the average cost drops by 70% for high volume example.