Novel process and product technologies used by MetaMateria are based upon capabilities developed for energy and environmental applications over the past 12 years. The focus has been to create higher quality water by the removal of nutrients and other contaminants. Some applications offer an economic return, such as in aquaculture where higher yields and less feed can be achieved. Another application is in Wastewater Treatment Plants. Our products enhance both the output & performance of existing equipment; as well as eliminating algae and bacteria growth in chemical free pools by recirculating water through the PO4 Sponge media where phosphorus can be maintained below 0.09 mg/L (ppm) to eliminate algae, slime and mold growth.

Learn more about MetaMateria Technologies

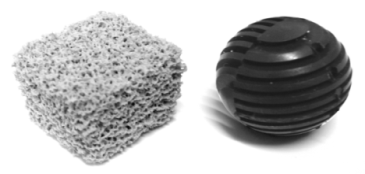

MetaMateria's Environmental Products start with liquid slurries that expand to create a highly porous, unique ceramic with an alumino-silicate binder allowing other additives to prepare a unique composite that can be used to enhance performance. Additives can include zeolites, iron powders, calcined clays, sulfur, and carbonate minerals.

This porous ceramic surface contains over 80% of open, interconnected porosity and has a density of 0.3 to 0.55 gm/cc. Surface area is typically ~15 m2/g but can be tailored up to 250 m2/g for some applications. These cost effective products are formed in molds, with a few examples of different shapes shown below.

These highly porous ceramics provide an ideal platform for supporting active materials, such as:

Beneficial Bacteria for growth of multiple bacteria colonies used for Bioremediation

Nanomaterials to breakdown or capture PO4 ions, trace organics, metal contaminants

Charged Ligands/Surfactants to capture perchlorates, chlorinated hydrocarbons, etc.

Water easily flows through this open porous structure in fabricated products. A tri-modal, hierarchical pore structure naturally creates water turbulence to enhance contact of contaminants in water, which facilitates removal by the beneficial bacteria, nanomaterials or other additives found on the pore structure surfaces.

Products can be packaged in many different ways, as seen below.